Well Testing

These days it has become much easier to run Clamp on meters

Clamp on Meters offers cost-effective, non-intrusive measurement methods for wells, flowline and overall field production surveillance. The underlying physics of most “Clamp” meters are based on the sonar flow principle and we promote this technology due to the ease and turnaround time of getting the test and getting the underlying result.

In Nigeria, we are the sole representative of a renowned flow metering vendor worldwide and have experienced and capable of hands for deploying the technology

APPLICATION:

UPSTREAM (US): All kind of wells, Natural Flow to Artificial lifted wells

DOWNSTREAM (DS): Topside pipelines, Water injection lines, Export lines, Facility dewatering lines

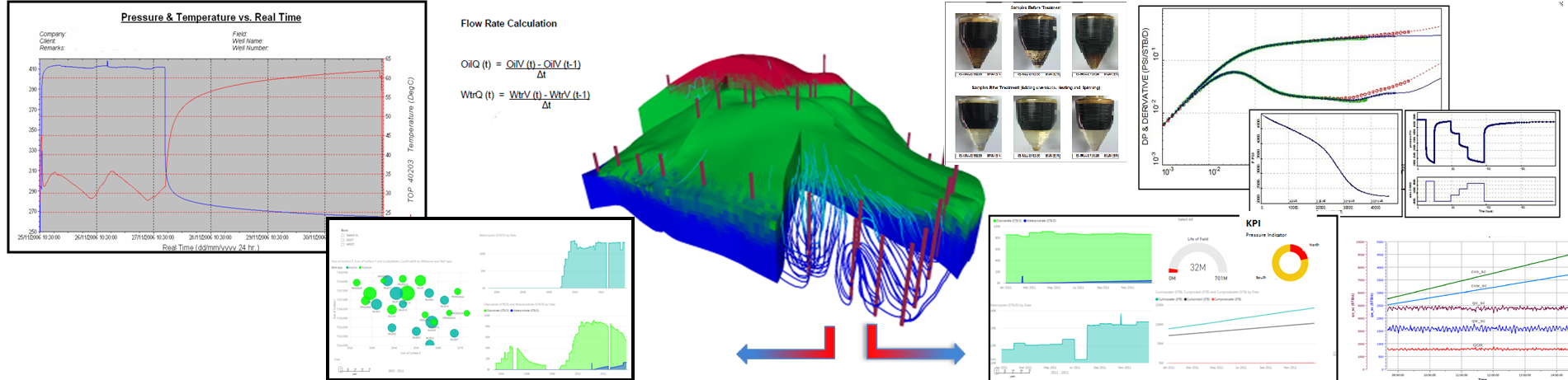

As a well surveillance solution, Well Testing is the first point of access to understand and diagnose the health of the US/DS production flow system.

Reservoir Monitoring

Continuous Downhole Data Acquisition Solutions can be made possible with the ability to use The ability to use downhole gauges to get uninterrupted pressure and temperature data to pro-actively detect real time problems gives the asset the opportunity to detect imminent challenges and hence leverage on the right actions to maximize well potential and minimize operating costs.

Acquiring Downhole “Sandface” Pressure and Temperature is a valid requirement these days, especially when reservoir monitoring and management is concerned. The ability to stay above the reservoir saturation pressure or conduct “Step rate test”, “Fall Of test” or “Draw Down” could be conducted on the fly for accurate reservoir diagnosis and immediate actions

We also provide a dashboard and user interface to create your customised workflows and hence adde more value from the data collected – See Reservoir Monitoring & Analysis

Artificial Lift Monitoring

Provide integrated 24/7 real-time well surveillance of installed ESPs and downhole Gauges, enabling increased production uptime, improved ESP run life and maximum recovery of reservoir potential.

Real time and historical data are analyzed by a team of reservoir engineering experts for optimal reservoir management and production optimization. This proactive approach ensures operational technical issues are flagged and addressed in a timely manner and remotely managed without the need of human intervention. Such minimizes the need for onsite field service manpower and reactive methods.

Enable remote field location well management; reduce reaction time, addresses driving and security risk exposure. The need for physical presence of technicians at wellsite to collect data, restart ESP after nuisance trips due to changes in a well or field operating condition are also eliminated.

+234-8055360998

+234-8055360998 enquiry@rhinoprod.com

enquiry@rhinoprod.com